BUILDING MATERIALS INDUSTRY

Automatic Brick Manufacturing Industry

Automatic Brick Manufacturing industry is the backbone of construction work and occupies one of the most important places in the urbanization of any country. Being a developing country, the demand of bricks is increasing day by day in Bangladesh. On the other hand, govt. is experiencing a period of flux, as pressures from environmental groups for emitting over 5.0 million tons greenhouse gas annually from this industry. So, Bangladesh govt. banned the manual brick or FCK from July 01, 2014.

Here, we from EPC, gathered several years of exposure in Auto-Brick manufacturing plants for construction and operation both. As for the technologies are new and designs are imported from offshore developed countries, performance efficiency is subject to successful implementation through incorporation of local geographical characteristics. Through rigorous R&D, EPC now owns the perfect solution (in context of Bangladesh).

IN AUTO-BRICK

MANUFACTURING INDUSTRY,

EPC OFFERED

TECHNOLOGIES ARE;

Premium Tunnel kiln technology for ceramic bricks

Tunnel kiln technology with car dryer (both 2-time, 1-time setting, Automatic/Manual operation

Hybrid Hoffman kiln technology (Automatic/Manual operation

TECHNICAL HIGHLIGHTS OF

EPC OFFERED TECHNOLOGIES;

FOR CERAMIC BRICKS

- ☉ Produces high quality bricks, commonly termed as ‘Ceramic Bricks’.

- ☉ Ensures higher durability of the structures build with this product.

- ☉ Robotic setup keeps the integrity of the bricks intact for flawless shape and color.

- ☉ High quality production is certain, irrespective of the moisture level in the raw materials.

- ☉ These bricks are less prone to algae and moss attack.

- ☉ Product demand is very high to government projects and premium customers.

- ☉High setup cost gets reimbursed through premium pricing and project stature.

TUNNEL KILN TECHNOLOGY WITH CAR DRYER (BOTH 2 & 1-TIME SETTING, AUTO/MANUAL OPERATION)

A: 2-TIME SETTING, AUTO/MANUAL OPERATION

- ☉ Provides better quality red bricks even with high drying sensitive raw materials. Automatic Operation costs more but requires less manpower at operation phase.

- ☉ Products from this technology are of high demand in urban areas.

- ☉ Setup cost is more than 1-time setting but operating efficiency is better when raw materials are exposed to high moisture condition.

B: 1-TIME SETTING, AUTO/MANUAL OPERATION:

- ☉ Capacity utilization is better compared to Hybrid Hoffman or Hoffman technology.

- ☉ Requires less manpower at operation phase.

- ☉ Project viability increases for of low drying sensitivity clay.

HYBRID HOFFMAN KILN TECHNOLOGY

- ☉ With 2 kilns, combined waste heat ensures better dry bricks than Hoffman technology.

- ☉ With 2 kilns, combined waste heat ensures better dry bricks than Hoffman technology.

- ☉ Product are of consistant quality, results higher demand.

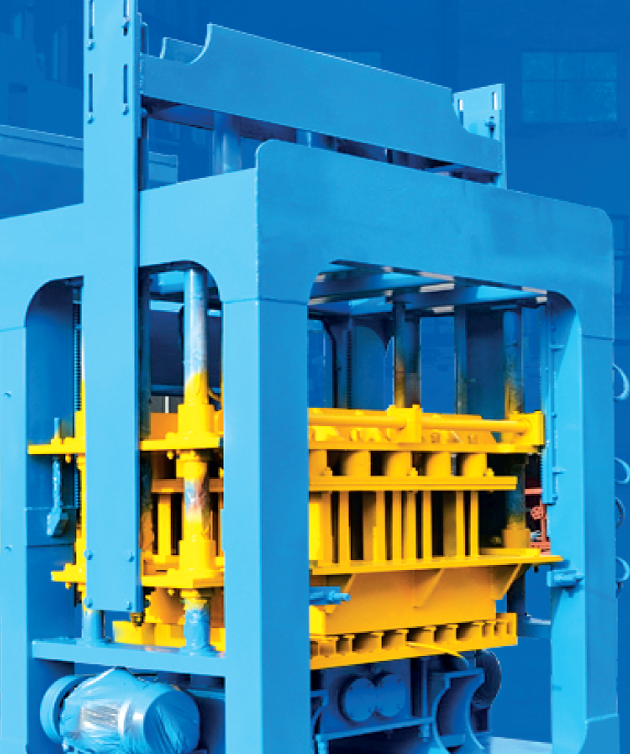

Concrete-Block Manufacturing Plants

Cement concrete hollow blocks have an important place in modern building industry. Blocks are cost effective and better alternative to burnt clay bricks. Its demand is increasing day by day and will be maximum within a few years. Raw materials of Concrete-Blocks are stone chips, pebbles stone, thick sand, stone dust, cement and water, which are not harming environment in any aspect.

In EPC Corporation Ltd., we acknowledge this industry for time of demand necessity for Bangladesh. It will not only save the fertile land of this densely populated country but also will incur less cost to the country’s growing infrastructure developments. Our highly experienced R&D team has worked for better solutions for Concrete Block making technologies for high efficiencies with less investments and now can successfully replicate any projects to international standard.

HIGHLIGHTS OF

CONCRETE-BLOCK

PRODUCTS ARE

At same size, blocks are lighter and hence building weight is low.

Blocks provide better resistance to earthquake.

Provides better facility for concealing electrical conduit, water and sewer pipes.

Building construction pace is faster with blocks for larger size and less mortar requirement.

Production cost, Product price and Profit margin is almost same.

IN CONCRETE-BLOCK

MANUFACTURING INDUSTRY,

EPC OFFERED

TECHNOLOGIES ARE

Semi-automatic hydraulic press vibration block technology

TECHNICAL HIGHLIGHTS

OF EPC OFFERED

TECHNOLOGIES

- ☉ Hydraulic press automatic Vibration block technology, requires only 4 labors to operate, reducing labor cost with improved efficiency.

- ☉ Frequency conversion control system is adopted in the vibration system and the motor speed is controlled by the low speed cruising technology, improving molding speed & product density.

- ☉ Double proportional solenoid valve and integrated hydraulic pump station to adjust oil speed, pressure and temperature, achieves higher stability, efficiency and energy savings.

- ☉ PLC control system is developed to the specific machine with self-diagnose function, ensuring fault-displaying and problem-debugging or indicating functions.

- ☉ Full automatic set-up incorporates seperate integrated PLC control unit for batching, neighing, mixing, coloring system which ensures efficient production and effective capacity output.

AAC Block Industry

AAC blocks are light weight Aerated Autoclave Concrete Block. It is manufactured through a reaction of aluminium powder and a proportionate blend of lime, cement, and fly ash or sand.

MINIMIZE COSTS AND SAVE TIME

WHILE MAINTAINING HIGH QUALITY STANDARDS

- ☉ Fire Resistant / Non-Combustible

- ☉ Superior Thermal Insulation

- ☉ Excellent Acoustic Performance

- ☉ Excellent Acoustic Performance

- ☉ Lighter Product Reduces Temptation cost

- ☉ Design Versatility & Flexibility

- ☉ Termite & Pest Resistant

- ☉ Reduced Time & Labor Costs

- ☉ Superior Durability

- ☉ Environmentally Friendly

Autoclaved Aerated Concrete (AAC) is one of the most sustainable building materials today. The unique product flexibility and characteristics allow for high-speed and energy-efficient construction methods. Comprised of all natural raw materials, AAC is going to be used in a wide range of commercial, industrial, and residential applications, especially for high rise structure.

AGRO FEED INDUSTRY

Bangladesh has a unique, hi-tech Feed Industry. The technologies are mostly imported from Europe, USA and a few from China. This industry maintains high standards & quality and ensures a ‘multi check-ups’ before marketing its products. Almost all the large commercial feed mills in Bangladesh have their own Testing Laboratories. More than 201 feed mills- large and small registered with Department of Livestock Services (DLS) in Bangladesh.

The per capita consumption of chicken meat and egg is still very poor in Bangladesh but there is a positive sign as the per capita income has been increasing along with the living standards. Along with this, the countrymen have now become more conscious about their health and nutrition. The present annual growth rate is approximately 15%-18%.

In EPC Corporation Ltd., we provide not only manufacturing equipment and technology, but also integrated solutions. Hence, quality feed products can be produced in a reduced operation cost, which is the key point in maintaining competitive advantage in market competition. We have always adhered to the concept of safe feed and food and integrate this concept into our products and projects to ensure green, clean and safe feed for our pets.

IN AGRO FEED INDUSTRY, EPC OFFERED TECHNOLOGIES

(TESTING LABORATORY INCLUSIVE) ARE

Automatic Feed Technology of 10 ton/hr from Germany and Belgium

HIGHLIGHTS OF THE EPC TECHNOLOGIES ARE

Types of Feed produced: Pellet, Mash, Floating and Sinking.

Poultry Feed range: Broiler, Broiler House Feed, Layer, Breeder birds and also for the Day-old-chicks (DOC).

Cattle Feed range: Dairy feed, Protein feed.

Fish Feed range: Starter, Grower and Finisher in both kind Floating and Sinking form.

Lab facility includes: Ingredient quality check, process control, finished feed quality check, control of toxic substances, including pathogenic micro-organisms etc.

PLASTIC INDUSTRY

Over the years the use of plastic products has been increasing by leaps and bounds in Bangladesh because of its intrinsic feature: it is durable, easily portable and affordable to the buyers as far as price is concerned. It is one of the emerging sectors in our economy with having a growth momentum at about 20 per cent a year on the back of ever-expanding demand from both home and abroad. In fiscal 2017-18, the domestic market size of plastic products hit Tk 25,000 crore, according to the Bangladesh Plastic Goods Manufacturers and Export Association (BPGMEA).

Plastic exports rose 31 percent year-on-year to $117 million last fiscal year, according to data from the Export Promotion Bureau. But Bangladesh has only 0.6 percent share of the $546 billion global plastic market.

There are innumerable items made of plastic used as household product, and as raw-materials in industrial and construction sectors. It mostly produces several types of extrusion material, moulding thermosetting conversion like manufacturing of PVC pipe, shopping bags, injection moulding products, garment bag, woven bags, PTE/PE bottle, laminated packages, rigid sheet, garments accessories, household products, medicine packs etc.

One indicator of future growth is that average plastic consumption in Bangladesh is about 2 kg per person. In contrast, in India it is 6 kg and 40 kg in Gulf countries and 10 kg in Southeast Asia. So this Industry is yet to uncover the boom

Woven Plastic Industry

Nonwoven Plastic Industry

Recycled Plastic Industry

CHEMICAL INDUSTRY

Bangladesh’s chemical imports have nearly tripled in the past decade, spurred by the rising demand from various industrial sectors catering to domestic and foreign markets. There is no industry where chemical is not required. Garments and textile sectors are the main consumers of the imported chemicals followed by pharmaceuticals, food processing, cosmetics and toiletries, leather, plastic and other sectors. Businesses brought in Tk 17,548 crore worth of chemicals in 2017-18, which was only Tk 6,103 crore in 2007-08, according to Bangladesh Bank (BB) data. Imports rose 12 percent year-on-year to Tk 7,772 crore in the July- November period of the current fiscal year, according to the BB. This is a huge existing demand market and rising industrialization fuels demand for chemicals.

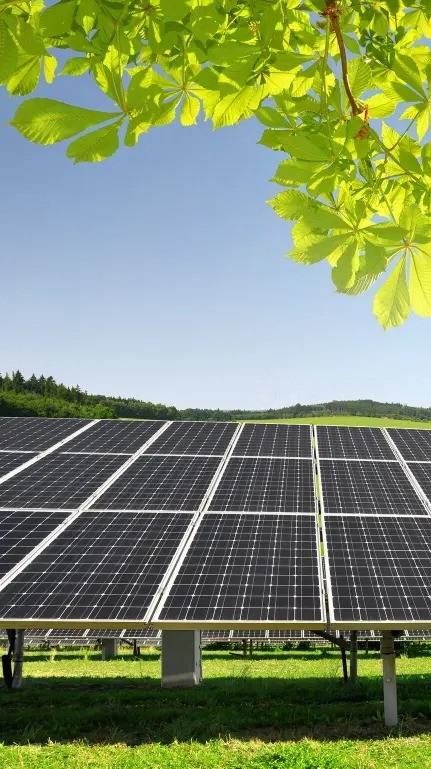

RENEWABLE ENERGY

Solar Power

LEADING THE WAY IN SOLAR POWER SOLUTIONS

We are proud to be at the forefront of the solar revolution, offering comprehensive Engineering, Procurement, and Construction (EPC) services for solar power installations. Our expertise spans across residential, industrial, and utility sectors, ensuring that we cater to a wide array of energy needs with precision and efficiency.

PARTNERSHIP WITH ENERPARC

Our strategic partnership with ENERPARC, a globally recognized leader in the solar industry, enhances our capabilities and service offerings. Headquartered in Hamburg, Germany, ENERPARC AG has an impressive portfolio of over 4,100 megawatts of installed solar power worldwide. Their extensive experience, dedicated team of photovoltaic specialists, and strategic partnerships in plant construction, certification, and safety, ensure that we deliver projects of the highest quality and reliability.

RESIDENTIAL AND INDUSTRIAL ROOFTOP SOLAR SOLUTIONS

In the residential sector, our rooftop solar solutions are designed to provide homeowners with clean, sustainable, and cost-effective energy. By harnessing the power of the sun, we help reduce electricity bills and carbon footprints, contributing to a greener future. Our systems are tailored to fit the specific energy requirements and architectural designs of individual homes, ensuring optimal performance and aesthetic integration.

For industrial clients, we offer robust and scalable rooftop solar power installations. These systems are engineered to support large-scale energy consumption, enhance energy security, and lower operational costs. By implementing solar power, industries can achieve significant savings and comply with stringent environmental regulations, all while maintaining uninterrupted production.

UTILITY-SCALE SOLAR PROJECTS

EPC (BD) LIMITED extends its expertise to the utility sector through Independent Power Producer (IPP) projects. Our utility-scale solar power plants are designed to generate substantial amounts of renewable energy, feeding into the national grid and supporting broader energy infrastructure. These large-scale projects are crucial for meeting the increasing energy demands of growing populations and industries, while also promoting sustainable development.

COMPREHENSIVE O&M SERVICES

We understand that the successful operation of a solar power system extends beyond its installation. That’s why we offer comprehensive Operations and Maintenance (O&M) services to ensure the longevity and efficiency of our solar installations. Our O&M services include regular inspections, performance monitoring, preventive maintenance, and prompt troubleshooting, all aimed at maximizing the return on investment for our clients.

COMMITMENT TO QUALITY AND EXCELLENCE

As EPC contractors, our commitment to quality and excellence is unwavering. We leverage our combined expertise and resources with ENERPARC to provide top-notch solar solutions that meet the highest industry standards. From initial consultation to project execution and beyond, we ensure a seamless and hassle-free experience for our clients, delivering results that exceed expectations.